- Jatro Renewables was founded in 2004 with partners

- Built first biodiesel plant near Dayton, OH and operated four years

- 2007 began installing biodiesel plants and mass transfer modular systems

- 2010 adapted “esterification” to allow use of lower cost oils containing up to 15% free fatty acid (FFA). Typically, only to 3% FFA could be processed.

- By 2012 the company developed a patented technology using Supercritical theory to process oils with up to 100% FFA

- Supercritical process lowers opex by about 35%

- Supercritical process provides for the use of inexpensive high FFA oils such as trap grease, jatropha and off spec. high FFA oils

- In 2015 company began offering a wider range of engineering services

- 2016, the first biodiesel plant using Supercritical technology was commissioned in Illinois and owned by CHS, Inc. and is co-located with a 110 million gallon per year (MMgy) ethanol plant

- Another Supercritial plant is under construction at a 59MMgy ethanol plant. In 2017 the project was awarded a $3.8m grant from California Energy Commission.

- In 2017 Jatro Renewables began offering a patented Renewable Hydrocarbon Diesel (ASTM D975) plant. One commercial system is currently running (since 2016) and another (formerly operating) has been moved to another location and currently under construction

- 19 biodiesel plants built and operating since 2004.

“We’re ready to design, build, and commission you a great plant . . . wherever you are!”

Raj Mosali, President

rmosali@JatroRenewables.com

Sabrina Pennington, CFO

spennington@JatroRenewables.com

Ian Lawson, COO

ilawson@JatroRenewables.com

Sales & Marketing

(937) 308-1230

845 North Main Street,

Miamisburg, OH 45342

(937) 663-3010

In 2015 Jatro Renewables moved to ”supercritical” technology and this eliminated the need for esterification and the use of a catalyst. Also, unlike the traditional process, distillation is added at the end to purify and render a clear biodiesel.

Jatro Renewables’ “traditional” biodiesel equipment at Vanguard Synfuels, Pollock , LA (2010). The above esterification system (using methanol and sulfuric acid as the catalyst) converts the feedstock’s free fatty acid (FFA) into biodiesel and will handle up to 15% FFA. The balance of the feedstock will be transesterified into biodiesel (using sodium hydroxide as the catalyst and methanol). All but about 11% of the methanol is recovered and re-processed to be used again.

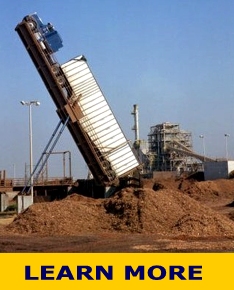

Within 3 about years we anticipate the main feedstock will be biocrude. This oil is derived from multiple biomass sources, but with a common thread: they are all cellulosic-based and deliver up to about 80% less harmful emissions than #2 diesel. Wood chips and switch grass are two examples of cellulosic biomass. Additionally, under the EPA’s Renewable Fuel Standard (RFS), the Renewable Identification Number (RIN) becomes a Cellulosic Diesel D7 RIN with a current (4/18) value of about $2.78/gallon.

Click To Enlarge Map

Copyright 2020 Jatro Renewables, Inc. | 845 North Main Street,

Miamisburg (Dayton), OH 453422

(937) 308-1230

www.JatroRenewables.com